Helical Screw Piles – Ensure Your Project Meets the Building Code.

Are your helical screw piles being installed correctly and do they meet the building code?

As you may or may not know, for over 30 years I have been running Your Deck Company, additionally I am a trained and certified installer for GoliathTech Helical Screw Piles. Furthermore, I have also been trained and certified by one of the largest global manufacturer of helical screw piles. When it comes to the foundation of your project, it is not optional to meet the building code. Therefore you must be aware of what is required to have a code compliant foundation when using helical screw piles.

Components of a GoliathTech Helical pile

We all know the great benefits of using helical screw piles such as:

- No frost heave

- Minimal ground disturbance

- Fast installation

- Can build on immediately after installation

- Eliminate messy concrete

- No excavation

- There is no soil to clean up

- Minimal damage to root systems….and the list goes on…

DO YOUR HELICAL SCREW PILES MEET THE BUILDING CODE FOR YOUR PROJECT?

However, lets not forget the bigger question. Do you know what to look for to ensure that your helical screw piles meet the requirements of the Ontario Building Code? Here is a quick list of what questions to ask your contractor.

- Are the mounting brackets on top of the piles properly attached to the actual pile?

- If they are connected, how is this connection made? Welding on site OR Bolting?

- Does the pile manufacturer have a CCMC for their piles?

- Do they have the proper Ministers Ruling to accompany the CCMC?

- Can they supply an Ontario certified engineer stamp of the pile layouts and loads prior to installation?

- Will they supply an Ontario certified engineer stamp for the Conformity Report for the pile installation that includes the piles, mounting head design AND attachment?

- Do they fully meet the G185 Standard of galvanizing (ACQ and CA approved for use with Pressure Treated lumber)

MY CONCERNS.

Helical pile foundations have been around since the early 1800’s. My issues are not with the helical piles. My concern is that with the influx of helical pile use in the residential market, as a result, there are several over-sites that are occurring. Most people seem to be focused on the positive factors and are overlooking the mandatory building code requirements. I have encountered numerous helical pile installers, contractors and building inspectors that are simply not installing, using and inspecting helical piles properly for the residential market. Consequently, time and time again I am seeing projects that do not meet the building code for different reasons.

Recently I was at a trade show. I had the opportunity to chat with a gentleman from another helical pile manufacturer. I questioned him on a few of the items that I was concerned about. However throughout my questioning, his answers were all the same… “I don’t care”. He was aware that I represent GoliathTech Screw Piles and that I am a trained and certified installer of helical piles. What he did not realize is that, not only do I actually care about my projects. I have dedicated countless hours to training and research. As a result, he was angry, confrontational and did not like that he was being called out on his obvious disregard for the building code.

My point here is, not all screw piles are the same and not all helical pile installations meet the building code. As a result, you need to ensure you are receiving a proper code compliant foundation for your project, not just the cheaper option.

Are the brackets on top of the piles properly attached to the actual pile?

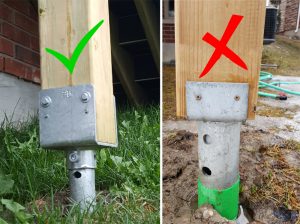

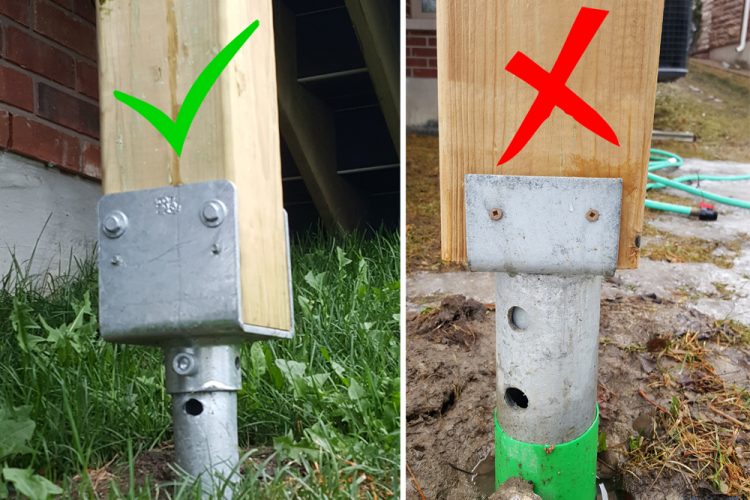

Three different helical screw pile installations. Only one meets the Ontario Building code for the decks they support.

The 3 images above are all supporting second story decks that are a minimum of 8 feet off of the ground. Assuming all 3 screw piles may be capable of carrying the required compression loading for the respective decks. However, the question is, do they still meet the actual Ontario Building Code for the decks they support?

Figure 1. Fully meets the Ontario Building Code. (constructed by Your Deck Company) GoliathTech Helical Screw Piles

- Properly bolted connection of the mounting head to the actual pile (The lowest bolt in the image)

- Galvanized to a G185 standard (ACQ and CA approved for use with Pressure Treated lumber)

- Proper size bolts into the 6×6 wood post also ACQ and CA approved (top 2 larger bolts with washers)

- Simpson Strong Tie structural rated screws as secondary support (2 smaller screws below the top 2 bolts)

- FULL size U bracket to fully support the 6×6 post. (no wood hanging over the edge)

- 1/4″ thick 90 KSI steel for the U bracket

Figure 2. Does not meet the Ontario Building Code.

- There is NO bolted connection of the mounting head to the pile (fails the required building code for uplift resistance)

- No welded connection of the mounting head to the pile (would not be acceptable for use with pressure treated lumber as the galvanizing would be destroyed therefore not being ACQ or CA approved)

- Lacking proper bolts attaching the U bracket to the 6×6 post

- Generic NON structural deck screws to attach the U bracket to the post (not rated for this application)

- Undersized U bracket not providing full support to the 6×6 (essentially rendering it into a 4×6)

- 3/16 thick unknown strength steel for the U bracket (minimum code requirement) (does not have larger holes for use with proper bolting patterns)

Figure 3. Does not meet the Ontario Building Code.

- NO bolted connection of the mounting head to the pile (fails the required building code for uplift resistance)

- The threaded rod is simply resting inside of the pile without any support or proper galvanizing.

- Essentially resting on a non connected thin generic washer (washer is starting to slip off of the pile and what weight could that washer really be able to carry?)

- 6×6 post is not fully resting on the flat plate (flat plate is supposed to be a U bracket)

- Generic NON structural deck screws to attach the flat plate to the post (Must be a proper U bracket for side bolting)

- Does not meet the G185 standard for use with pressure treated lumber (threaded rod is zinc coated not Hot Dipped Galvanized to the proper thickness) Cannot verify thickness of remaining galvanization.

Consequently, these issues with helical screw piles are more common than you may want to believe. At least for my area of Ontario, contractors seem to have a complete disregard for the building code requirements, or a lack of training and education. In my opinion, one of the most important aspects of any project is the foundation. Are screw piles far superior to concrete? Yes they are. However, when using them, do not just focus on who can start tomorrow….or who has the lowest price. Due to the information above, you must ensure that your foundations meet the building code requirements.

But I have a permit? Will my helical screw piles be installed to the building code?

You might be wondering, “What about the building inspectors? I have a permit? Shouldn’t they catch this?”. The simple answer to this is yes they should catch this. However, as shown above figure 2 and 3 both projects were permitted and the building inspectors should have noticed these issues. It seems that the problem in this area is an honest lack of training for the residential market. Therefore when a project involves the installation of helical piles, the building officials defer to the manufacturer of the helical piles. The building officials request what is referred to as a “Conformity Report or Letter of Conformity”. Once the inspector has this document, they are satisfied with the pile installation and do not seem to take any further notice of the piles or the mounting heads.

Therefore, it is not an optional item, you must have a positive connection under the Ontario Building Code. The following chart outlines examples of when a connection is required.

Overview of the Ontario Building Code pertaining to the connection of a helical screw pile to the project.

Ontario Building Code and the connection required for a concrete foundation.

Requirements for attachment to Concrete – Helical Screw Piles require the same positive attachment.

Embedding the U bracket or saddle bracket into concrete is mandatory under the building code. Generally the saddle must be embedded into the concrete a minimum of 4″ and in some areas 6″. Therefore with this positive connection, the requirements for uplift in Ontario Building Code are satisfied. It seems to me that any contractor that has worked with concrete foundations in the past should be aware of the need for this connection. Therefore, I am curious how it can be ok that this connection is not always made when it comes to helical screw piles? Oh that’s right…. Its not ok.

Engineers letters or Conformity reports after installation……What are they really saying?

I will expand on this at a greater length on another blog post. However, for now I will say simply, these letters have traditionally and from everyone I have seen, ONLY covered the actual helical screw pile installation for tension and compression. Therefore, I have not seen them cover the connection of the pile to the mounting bracket. Additionally, I have not seen them cover the strength of the mounting heads or washers. As a result, it seems that building officials, contractors and homeowners have been placing blind faith in these incomplete letters that only seem to certify the actual screw pile and nothing else.

In conclusion, I think it is necessary for there to be more training and education on this topic to ensure the proper full installation of helical piles including how they attach to your project.

- Helical Screw Piles – Treated Lumber ACQ Corrosion Issues - July 14, 2017

- Helical Screw Piles – Ensure Your Project Meets the Building Code. - July 9, 2017

- Helical Screw Piles – What are they and what do they do? - July 4, 2017