Helical Screw Piles – Treated Lumber ACQ Corrosion Issues

ACQ approved: What you need to know about corrosion and how it affects the helical screw pile foundations and the metal connectors supporting your deck.

Decks are a fantastic addition to any home. A well constructed deck should provide you and your family with

Correct joist hanger, wrong nails

What types of Treated lumber are most common for residential use?

There are two main types, ACQ (Alkaline copper quaternary) or CA (Copper azole) treated lumber

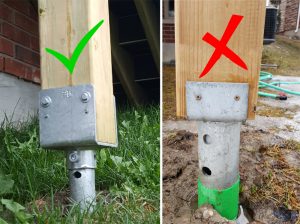

Clear example of ACQ leaching from treated lumber

As you can see from the image posted here, this is a deck post that is only 2 months old. The effects of ACQ leaching out of the wood happen quite quickly. Due to this staining from the ACQ is quite predominant and highly corrosive to non ACQ approved metal components.

What does this mean for your deck?

ACQ and CA treated lumber were introduced to the market after there was a voluntary regulation change in

The premature failure of a joist hanger affected by ACQ treated lumber

How does this affect Helical Screw Pile Foundations?

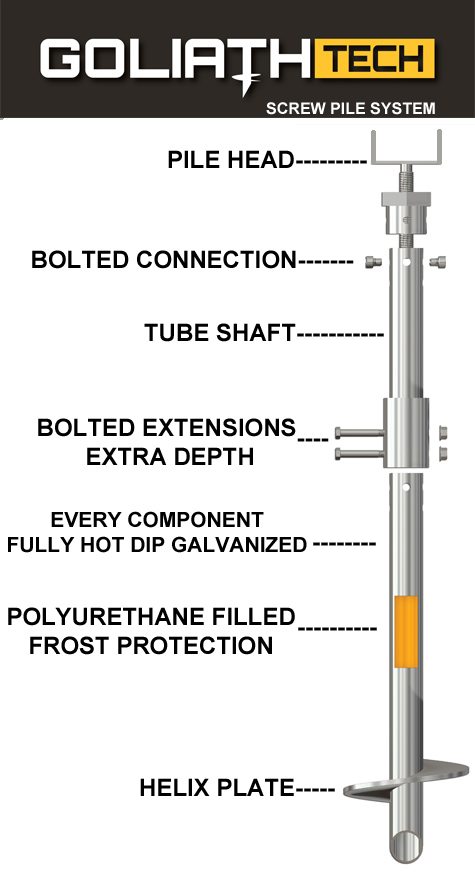

As an industry leader, GoliathTech helical screw piles are rated for use with ACQ and CA treated

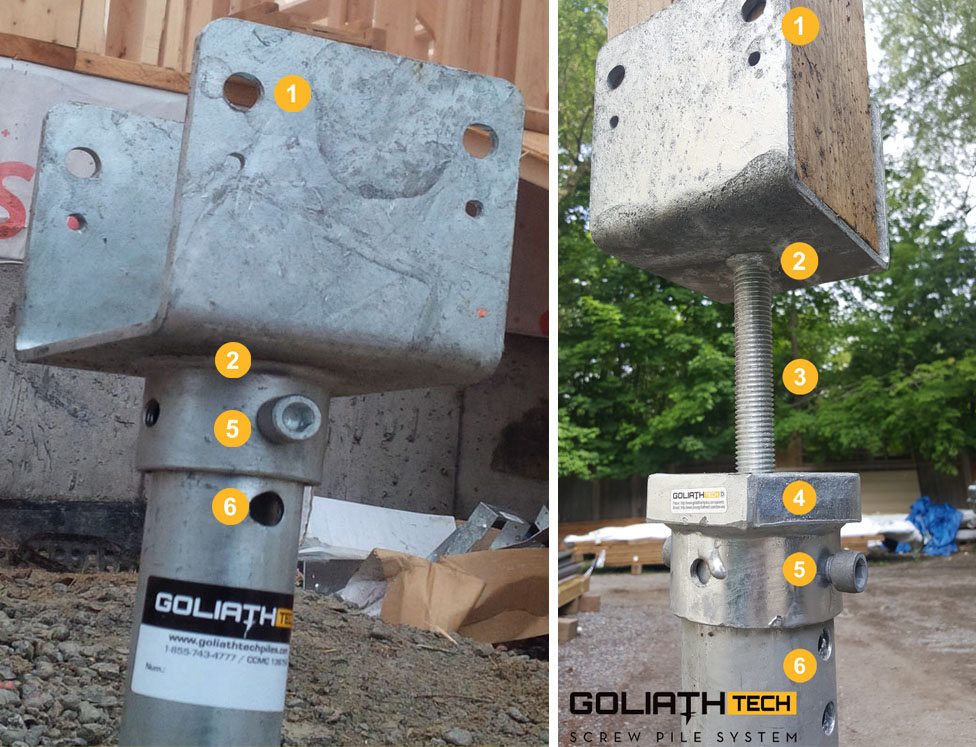

ACQ approved GoliathTech screw pile deck foundatio

How can I avoid this problem for my fasteners?

The solution is simple. The basic rule is to ensure that any metal products used in the construction of your deck are CA or ACQ approved. Because of this corrosion issue, there are several manufacturers that create specialty metal fasteners and connectors rated for use with ACQ and CA lumber. However, you do need to ensure that your contractor is aware of this issue and is using all of the right hardware (not just the cheapest options available). Yes, this will add to the cost of your new deck. Therefore, all metal hardware used for decks must be CA or ACQ approved.

What are my options?

One option is to use products that are ACQ approved hot dipped galvanized to a G185 thickness. Alternatively where available, stainless steel fasteners are a great option too. As you can see in the supplied images,(especially the main title image) the metal connectors have failed yet the wood is still structurally stable. Therefore, at Your Deck Company, we take every effort to ensure that the products we use are all rated for use with ACQ and CA treated lumber. Products that are not ACQ approved are simply not acceptable.

How much more corrosive to metal can ACQ or CA really be?

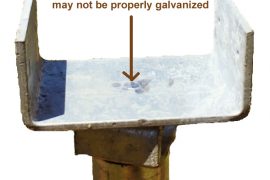

Non galvanized U bracket corrosion

ACQ and CA treated lumber are up to 6 times more corrosive to metals than previous CCA treating chemicals. Newer wood preservatives are far more corrosive, and in certain cases have caused rapid failures. Research has shown that the corrosion rate in ACQ treated wood is between 2-6 times greater than wood treated with CCA. Due to this corrosion, the expected service life of a common deck nail has decreased by more than 90%. Previously, a G90 coating was required for CCA pressure treated lumber. In order to protect against the increased corrosion rate from ACQ and CA, the industry recommendation has been increased to a G185 coating or better. The hot dipped galvanized G185 coating corresponds to a coating weight of 1.85 oz. of zinc per square foot (565 g/m2)

What deck components must be CA and ACQ approved?

Helical screw pile mounting head U bracket

- Complete helical screw pile and assembly (pile, mounting head etc.)

- U bracket or Saddle brackets

- Nails and screws

- Bolts, washers and nuts

- Joist Hangers

- Flooring Clips

- Aluminum railings (generally a rubber gasket is used as a barrier)

- Post to beam connectors

- All metal components

What to look for when using helical screw piles: ACQ approved.

Helical screw piles must be properly Galvanized when used with ACQ and CA treated lumber. With regards to height adjustable mounting heads, or fixed heads, there are 6 main items to consider. All of these items must be CA or ACQ approved for use with treated lumber, especially any metal in direct contact with the treated lumber.

What to look for in a mounting head for a ACQ approved screw pile

- Full size U bracket (saddle bracket) to properly fit a 6×6, 4×4 or 8×8 post. Provided with proper size holes to allow for proper bolts to connect the U bracket to the respective post. G185 galvanized for use with treated lumber. 1/4″ thick 60 KSI steel U bracket or flat plates.

- Threaded rod or stem is properly welded to the U bracket. Important to note that for some companies, this connection is NOT a welded connection. There is a small hole in the U bracket that accepts a small nipple on the end of the threaded rod. This small nipple is then hammered down to form a type of mushroom over the U bracket to hold it in place. (see previous image detailing a hammered connection) Also G185 galvanized thickness.

- 1″ thick threaded rod is G185 galvanized for use with ACQ and CA.

- 1″ thick hex head to distribute the loading over the entire pile. Beware that this part can be as thin as a 1/8″ thick washer.

- Galvanized and bolted connection to the pile to prevent uplift. This connection is required under the Ontario Building Code. GoliathTech has a patent on the height adjustable head design.

- Helical screw pile galvanized to G185 for approved use with ACQ and CA treated lumber.

Examples of failures on decks less than 10 years old

2 saddle brackets that have failed and one done properly.

- Image 1. In under 10 years, the U bracket (saddle bracket) has suffered total failure due to contact with ACQ treated lumber. Interesting to note is that the treated lumber 6×6 post is in excellent structural condition.

- Image 2. This deck was replaced for a new low maintenance Trex deck. However the U bracket used was properly galvanized and suffered very little corrosion due to contact with the treated lumber.

- Image 3. This deck is only 7 years old and the U bracket, bolt, washer and screws are fully covered with rust and will fail before the wood supporting post fails. The wood post is in good structural condition.

In conclusion, ACQ and CA treated lumber when in contact with metal, can dramatically reduce the life span of metal fasteners, supports or hardware. Therefore, it is important to ensure that all components used to build any structure with pressure treated lumber is compatible for use with these types of treated lumber.

- Helical Screw Piles – Treated Lumber ACQ Corrosion Issues - July 14, 2017

- Helical Screw Piles – Ensure Your Project Meets the Building Code. - July 9, 2017

- Helical Screw Piles – What are they and what do they do? - July 4, 2017